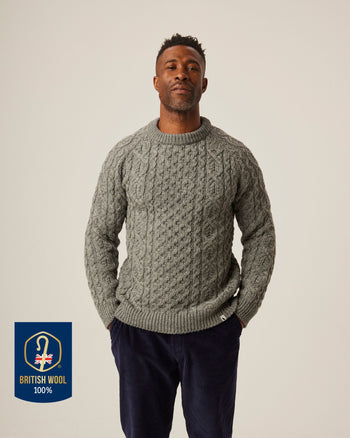

Buy British. Buy less. Buy better.

We’re one of the oldest clothing brands still manufacturing in Britain today. And since we use predominantly local, natural materials in the production of our garments, we’re already ahead in terms of sustainability. However, as one of the world’s biggest polluters, we believe the fashion industry (and its customers) have a big part to play in protecting the planet.

Traceability

We’re a small, family-run business who are passionate about being transparent in our materials and manufacturing process. This is so you can shop with confidence that we are doing everything we can to be a sustainable as possible.

-

United Kingdom

-

United Kingdom

-

West Yorkshire

-

Pennines

-

Manchester

-

Coventry

Sent to you

Growing

United Kingdom

We work closely with British Wool to source the best fleeces for our knitwear. Different breeds mean different wool qualities. For great natural elasticity, there’s the Border Leicester. When it comes to the perfect, naturally coloured wool, our favourite is the Black Face Welsh Mountain. And if it’s strong fibres you need, you can count on the Zwartbles or Llyen. By mixing and matching, we get the perfect blend.

Shearing

United Kingdom

Shearing keeps sheep cooler during the warmer months and reduces the chances of them becoming ‘rigged’ — in other words, stuck on their backs. It also minimises the risk of flystrike: a condition where maggots hatch in dirty areas of the fleece and eat through the skin. Many believe that mulesing (a procedure that involves removing skin from around the backside) can prevent flystrike. But in reality, it’s just brutal and cruel. We only source 100% guaranteed non-mulesed wool. We love wool. But we love the sheep that make it, more.

Scouring

West Yorkshire

Once our fleeces are sheared, they’re sent to Haworth Scouring in West Yorkshire. Haworth is one of the largest, most modern and environmentally responsible commission wool scours in the world. It’s where grease, dirt and debris are removed from our fleeces before they’re rinsed and dried — all without damaging the fibres or altering the natural qualities of the wool.

Spinning

Pennines

The next stop on our wool’s journey is a visit to Shepley Yarns. Tucked away in the village of Diggle, at the very heart of the Pennines, this is where our wool is spun into yarn ready for knitting. Shepley Yarns prides itself on sustainability and keeping to age-old techniques. Because sometimes you just can’t beat doing things the old-fashioned way.

Knitting

Manchester

Finally, our wool finds itself at one of our factories. While we use several factories to make our shoes, shirts and jackets, all of our knitwear is made at our factory in Manchester. We’ve always maintained a close relationship with all our designers and manufacturers. And from the initial designs to that final finishing stitch, each and every one of our knitted garments is proudly made right here in the UK.

Materials

Warm in winter, cool in summer, and as hardy as the sheep that wear it to begin with, wool is a wonder to work with. Each fibre has both a left and right-handed helix at its core - or, in other words, a small, super-powered spring. Bend it any which way, as many times as you like, and it will always bounce back into shape.

We care about where our wool comes from. That’s why all the wool we use in our clothing is reared and sheared right here in Britain. We’re fully licensed with British Wool - the approved provider for wool handling in the UK. And since there are more sheep breeds here than anywhere else in the world, we’re pretty spoiled for choice when it comes to choosing the best fleeces to knit with.

Merino wool is up there with the softest of the soft, so you’ll find it in the majority of our knitwear.

Just like other wools, Merino is super breathable, warm, has antibacterial properties, and is even biodegradable. This means that, unlike synthetic materials that shed fibres during washing (we’re looking at you polyester and nylon), it breaks down harmlessly in water.

Merino comes with the added bonus of having more natural oils than other wools, so you won’t need to wash it as often. An even bigger tick in the sustainability box.

British Millerain & Halley Stevensons

We work with the world’s leading, UK based manufacturers and innovators in waxed cotton and weatherproofed fabrics to create our Wax Jacket collection. Our suppliers have unique technical knowledge and manufacturing experience over generations of development and innovations.

Our waxed cotton is durable, water-resistant, and has an authentic, antique finish. Think all the character of an old pair of jeans with the lived-in look of well-worn leather.

Our Dry wax jackets have all the same benefits as a classic wax jacket but with a stylish matt finish. So for those looking for something a little less traditional with all of the same perks dry wax is the way to go.

The cleaning process is similar to a wax jacket however when rewaxing we recommend a dry wax reproofing spray.

Widely considered to be the best in the business, Abraham Moon has been crafting tweed at its Yorkshire mill since 1837. Made from 100% natural wool and woven with Northern soul, Moon fabrics have been crafted into everything from tweed coats to tartan. And according to its makers, the tweed is a material that can withstand wear and tear to last a relative lifetime.

Care & Rewaxing

Wax Jackets

Rewaxing

We recommend using Mallin & Son - the world’s busiest wax cotton workshop and the best in the business when it comes to rewaxing.

Visit their site to discover more about general wax jacket repairs.

Care

All of our jackets are made from waxed cotton in order to make them shower-proof and weather resistant. Wax jackets are notoriously difficult to clean so please take care when looking after yours. We do not recommend using a washing machine or dry cleaning your jacket.

Antique wax

This classic cotton waxed material is used in jackets such as the Bexley and the Clifton Wax Jacket.

Start by brushing off any loose dry dirt with a soft brush or a damp sponge. If there are any particularly stubborn areas, use a soft piece of cloth, cool/warm water and a gentle natural detergent. Do not use a degreasing soap, such as dish soap.

After cleaning your jacket, it may need rewaxing. Browse our Halley Stevenson's reproofing range here.

Dry wax

Our dry wax jackets, like our Fell jacket and Ladies Oversized Parka, have the same benefits as a classic wax jacket but with a slightly matte finish.

To clean your jacket, we recommend following the same process as you would with our antique wax jackets. However, when it comes to rewaxing, use a dry wax spray such as Nikwax’s cotton-proof spray.

Garment Care

Projects & Promise

We’re big believers in keeping manufacturing miles to a minimum, supporting British farmers and factory workers, and doing everything we can to curb our carbon footprint. Sustainability is a big part of what we do at Peregrine, but we know there’s always more to be done.

Sustainable Futures: Supporting Regenerative Farming in the UK

By supporting regenerative farming in the UK, we’re working to improve biodiversity, reduce environmental impact, and protect farmers’ livelihoods—one woolly step at a time.

How waste wool from our factory is being used as eco-friendly insulation

We reduce (and reknit) waste wool wherever we can. However, we’ve recently gone one step further in our efforts to re-use our offcuts and reduce our carbon footprint.

Why preserving British peatlands can help us to become net zero

We want to do more to offset our carbon emissions. So we’re taking part in a new net zero project that’s focused on preserving peatlands in the British countryside.